Auxetec technology

Advanced Auxetic Elastomers

Auxeticity – the tendency of a material to become thicker rather than thinner when stretched – is an unusual phenomenon. While the property is uncommon, it’s not unheard of. In nature, to take a few examples, it can be seen in places like the achilles tendon, cat skin and zeolites. But what makes this behaviour attractive is that auxeticity gives materials an edge when it comes to absorbing shock, as well as resisting fractures and tears. That makes them promising in applications where materials need to be durable, such as body armour and glass for buildings and vehicles.

Because of this, researchers have used a number of innovative approaches over the last 40 or so years to create synthetic auxetic materials. One thing all auxetic materials have in common is a negative Poisson’s ratio: the measure of the expansion of a material perpendicular to the force being applied to it. By 3D-printing or otherwise forming complex, porous geometries – honeycomb structures or perforated sheets, for example – it’s possible to create auxeticity in materials that would ordinarily show a positive Poisson’s ratio. However, the porosity required of these materials introduces inherent weaknesses, and the complex manufacturing processes often needed additionally make them expensive to produce. That’s what Auxetec, a spin out from the University of Leeds in the UK, is addressing.

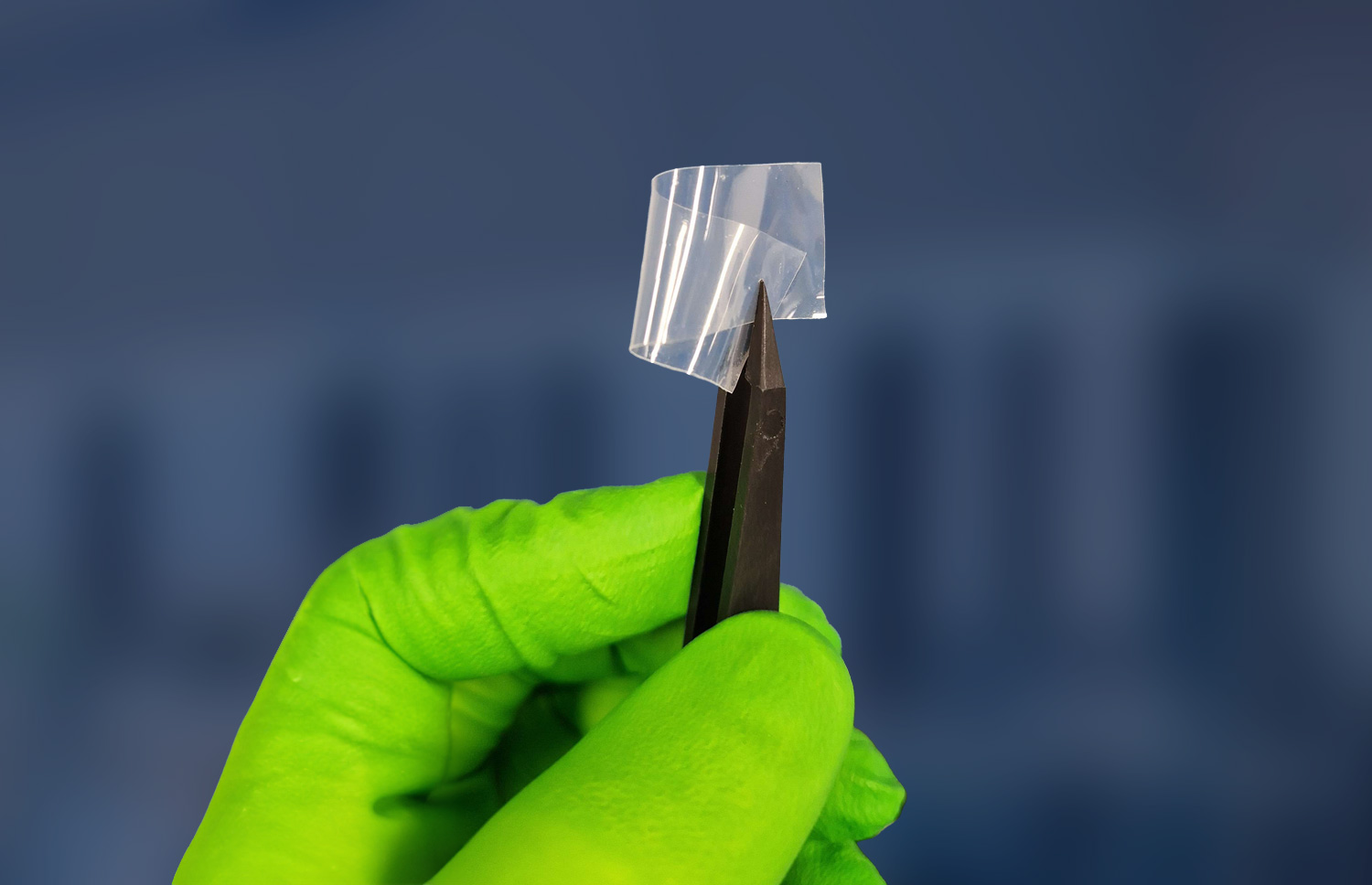

Auxetec’s groundbreaking technology uses optically clear liquid crystal elastomers. These thin (30-100 micron) films can be integrated into existing complex materials systems. We have a broad suite of granted patents in key global markets.

This novel, technology is tuneable, and can be tailored to address unmet needs within the Advanced Materials sector to provide:

Technical development programs undertaken both internally and with partners deliver tailored and samples which can be used to validate improved performance in specific applications.

Market application areas we are working on include:

We look forward to understanding how we can tailor and integrate our technology to add value to your next generation Advanced Material Products and Solutions!